— Simple and Effective Way of Combatting Bulking Sludge

Sludge bulking is a common occurrence in industrial wastewater treatment plants (WWTP) where activated sludge process is applied. It results in poor effluent quality. Attempts by operators to combat this by installing Biological Selector/Contact-tank often prove inadequate and sometimes may make it even worse. Dosing chemicals (either bactericide like chlorine, or coagulant such as Al or Fe salts) is another solution but will increase operation cost and has negative environmental implications.

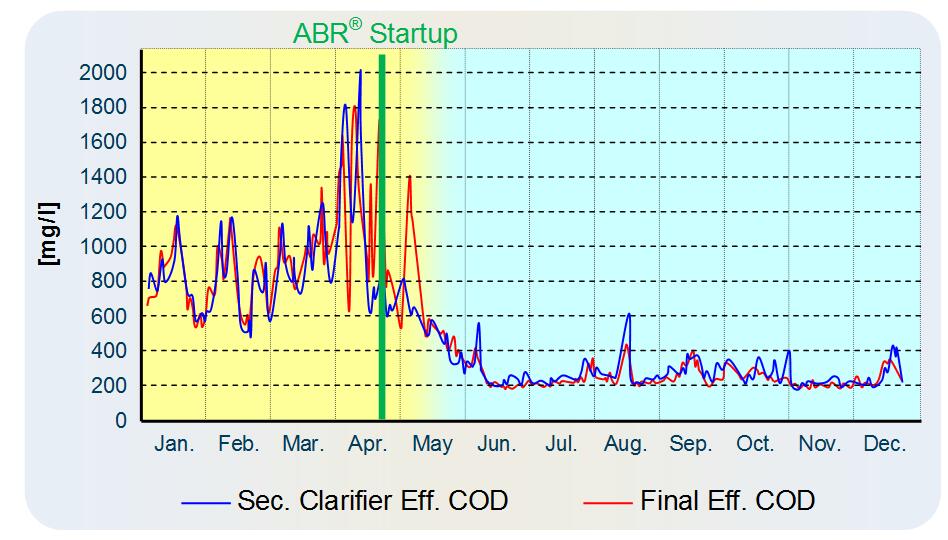

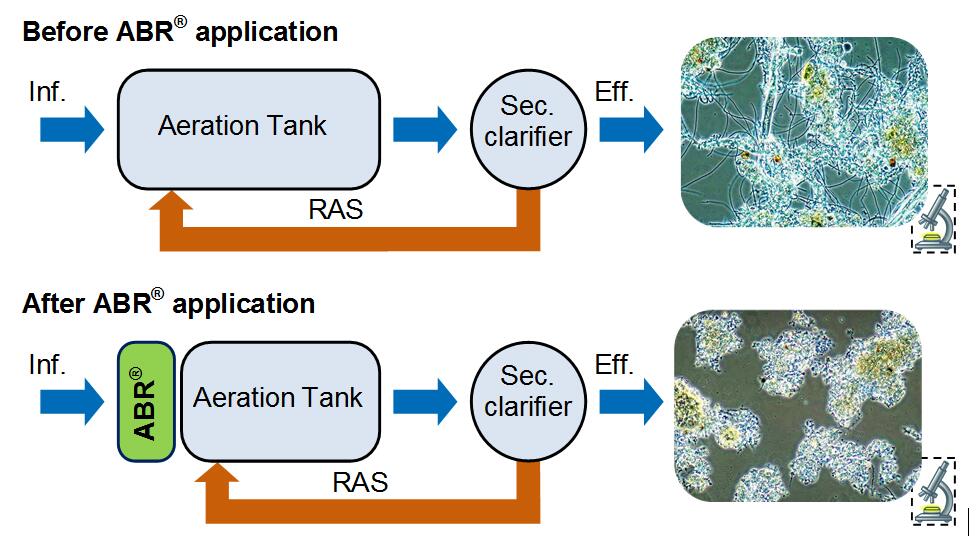

Sludge bulking is mostly caused by overgrowth of filamentous bacteria in sludge. Years of research found that the highly biodegradable substances in water are in favor of filaments, which can use them better than floc-former thus outcompete the latter. The ABR® (Anti-Bulking Reactor) quickly and permanently solves this problem by taking out the easy biodegradable substances before wastewater gets into aeration tank of activate sludge system.

ABR® is a pre-aerated unit deployed before the aeration tank. Its design greatly facilitates the multiplication of fast-growing microorganisms feeding on easy substrates which are therefore removed in a short period of time. Hence the HRT of ABR® unit is short (a couple of hours). And the prevailed growers wash out the unit with effluent in form of free-moving, individual microorganisms. However, due to very high growth rate, these microorganisms grow fast and keep the ABR® unit in an equilibrium status. As continuous removal of easy biodegradable matters, filamentous bacteria can not achieve sustainable growth in the system, the sludge bulking is thus prevented.

The ABR® has been successfully applied in many industries (pulp and paper, chemical, petro-chemical, food and beverage etc.) where the performance is well proven.