DHV BEEC: Nereda® - the Best Water Technology Breakthrough

Author: BEEC Update: 2022-07-11

In the context of increasingly stringent requirements for water environmental protection, many key regions and river basins such as Jiangsu, Zhejiang, Anhui, Yunnan, Guangdong, Hebei, etc. have successively promulgated and implemented local standards which is stricter than Class 1A in Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant. The promulgation and implementation of these standards have put forward higher requirements for the treatment capacity of sewage treatment plants, especially the discharge standards of nitrogen and phosphorus in effluent are more stringent. Therefore, the sewage treatment process with the functions of nitrogen and phosphorus removal is an inevitable choice to solve the high discharge standards.

The Nereda® process is one of aerobic granular sludge (AGS) process. It is a new- type of water treatment process with excellent nitrogen and phosphorus removal performance which was developed in the 1990s, by a close cooperation between Royal HaskoningDHV (RHDHV) and Delft University of Technology. It has been applied to practical projects since 2005, and has been widely promoted around the world. As of June 2022, more than 50 wastewater treatment facilities using the Nereda® process are in operation in Europe, Africa, Australia, North and South America. At present, its total treatment capacity has exceeded 13 million population equivalents (about 2.6 million m3/d). After years of engineering practice and application, Nereda® is now a well-proven and award-winning technology, which has been designated as the Best Water Technology Breakthrough of the past decade by the authoritative media GWI (Global Water Intelligence). Among the projects that have been completed and put into operation, there are many large-scale sewage treatment plants with a daily treatment capacity of tens of thousands or even hundreds of thousands of tons, which can be applied to municipal and industrial sewage treatment plants of different scales. At present, the Nereda® process has entered China and a full-scale treatment plant has been built.

Nereda® Utrecht WWTP , Netherlands (the winner of 2019 Wastewater Project of the Year by GWI)

Unlike traditional activated sludge processes which use flocculent sludge or biofilm systems, the microorganisms that treat sewage in the Nereda® process can spontaneously aggregate into granular sludge without the need for a carrier. The size of aerobic granular sludge is large, and oxygen and pollutants in water cannot all enter and penetrate into the core of the granule, so a concentration gradient is formed in the radial direction of the granlue. For example, the closer to the sludge surface, the higher the oxygen concentration it gets, and thus the oxygen-enriched area is formed near the surface, however, the anoxic area is formed inward, and even gradually transitions to the core of the anaerobic area . In different spherical layer, there are respective dominant microbial populations, which have been confirmed by a large number of fluorescence in situ hybridization (FISH) analysis in microbiological research. The structure and unique properties of the above-mentioned aerobic granular sludge make it possible to achieve high-efficiency removal of COD, BOD, nitrogen and phosphorus simultaneously in granular sludge, consequently having excellent nitrogen and phosphorus removal performance.

Advantages of Nereda® Technology

Nereda® technology does not use membranes or plastic media supports at all, and its self-aggregating aerobic granules have superb settling and resilience characteristics and are suitable for a wide range of flow/water quality, climatic conditions and treatment objective. The sewage can be highly purified in a compact reactor, and the energy consumption and chemical use can be greatly reduced, which can decrease up to 75% of the footprint of conventional biological treatment systems , and save up to 50% of energy consumption compared with traditional treatment processes. Nereda has unparalleled whole life cost. The superior biological nitrogen and phosphorus removal abilities ensure the excellent effluent quality of the Nereda® process, simplified post-treatment, and recovery of phosphorus and high-value biopolymer from granular sludge. Nereda® technology can be used as a cost-effective and sustainable solution for wastewater treatment in greenfield wastewater treatment plant projects, as well as in reconstruction, expansion or upgrading of existing wastewater treatment facilities.

DHV BEEC - Nereda® Technology Licensee

DHV (Beijing) Environmental Engineering Co., Ltd. (DHV BEEC) is the official licensee of Nereda® technology in China. In the field of wastewater treatment, DHV BEEC holds and has been licensed to a series of world-renowned patented/proprietary technologies and products (including Carrousel® oxidation ditch, Crystalacor® pellet reactor, Nereda®), and has extensive application achievement and good market reputation in all societies and industries. In addition to participate the process design and parameter determination of Nereda® in the design stage, DHV BEEC is also the exclusive supplier of Nereda® core products, including the special internals equipment for Nereda® reactor plus the intelligent controller of Nereda® unit, and DHV BEEC is responsible for the equipment delivery, installation guidance, process start-up and operation management support, etc.

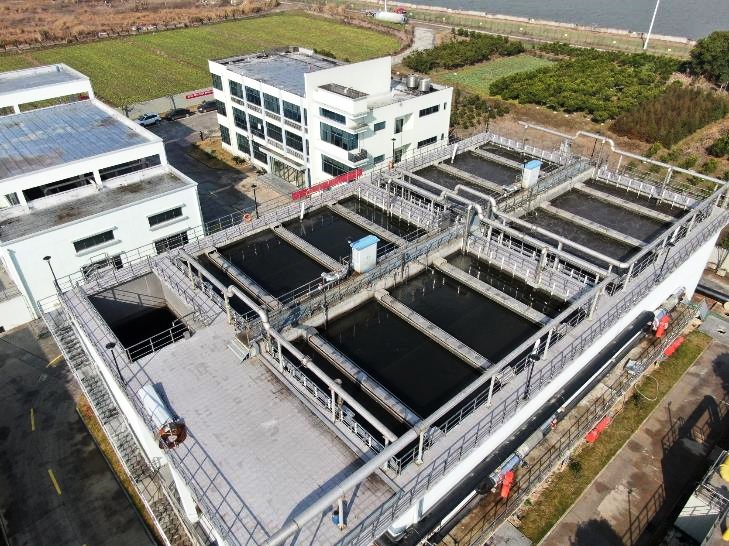

The First Nereda® Wastewater Treatment Plant in China

Through cooperation with RHDHV Company, DHV BEEC built the first domestic sewage treatment plant (with a treatment capacity of 20,000 m3/d) using the Nereda® process in 2019, which was put into operation in early December, and the final effluent after treatment reached Discharge Standard of Major Water Pollutants for Municipal Wastewater Treatment Plants in Zhejiang Province (DB33/2169-2018).

Domestic Nereda® WWTP influent/effluent water quality

|

Parameter |

Units |

Influent |

Nereda Effluent |

Final Effluent |

|

|

Design Value |

Monitoring Value |

||||

|

BOD5 |

mg/1 |

200 |

≤ 10 |

≤ 10 |

Up to standard |

|

CODcr |

mg/1 |

500 |

≤ 50 |

≤ 40 |

Up to standard |

|

SS |

mg/1 |

200 |

≤ 15 |

≤ 10 |

Up to standard |

|

TN |

mg/1 |

45 |

≤ 12 |

≤ 12 |

Up to standard |

|

NH4-N |

mg/1 |

30 |

≤ 1.5 |

≤ 2 |

Up to standard |

|

TP |

mg/1 |

2.5 |

≤ 1 |

≤ 0.3 |

Up to standard |

|

pH |

- |

6~9 |

6~9 |

6~9 |

Up to standard |

It should be noted this Nereda® WWTP started up under the condition of winter low water temperatures and was affected by unfavorable factors such as disruptions due to the COVID-19 pandemic, but the Nereda® system performance was still fully achieved design requirements within a few months, and the Nereda® system has excellent nitrogen and phosphorus removal performance. The long-term operation energy consumption is significantly reduced, showing great advantages compared with conventional treatment processes.