Compared with other convention treatment processes, Nereda® has the following advantages:

• Cost-effective (both CAPEX & OPEX)

◦ tank volume substantially reduced by 50% - 75% due to compact (“one-tank”) and uncomplicated design and concentrated biomass (MLSS is up to 7 - 12 g/l)

◦ up to 50% lower energy consumption and minimized chemical application

◦ operation & maintenance cost much lower thanks to less amount of mechanical equipment, minimum chemical consumption

• Easy to operate

◦ less equipment (e.g. clarifiers, return sludge pumps, moving decanters etc. are not necessary)

◦ robust performance thanks to unique nature of granular biomass

◦ every Nereda® plant is equipped with an AquaSuite®Nereda®Controller, a smart, integrated process controller ensuring fully automated plant operation and reliable performance

• Sustainable

◦ lower energy consumption (up to 50%) results in lower carbon footprint / greenhouse gas emission

◦ minimum use of waste generating chemicals reduces impact on environment

◦ The LCA (Life Cycle Assessment) conducted by prominent institute confirms better environmental profile of Nereda® on all environmental categories

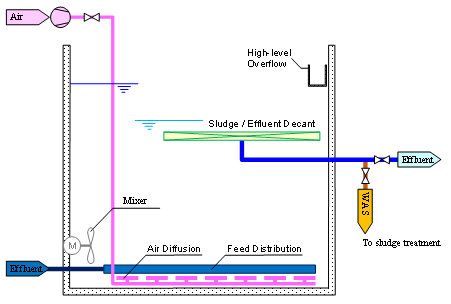

—SBR AGS Reactor

In view of the current situation and demand in China of wastewater treatment market (for example, there is a large demand for upgrade of existing plants and in-situ capacity expansion, and the opening is quite big in treatment facilities and capacities in heavily polluting industries such as pharmaceutical, chemical, dye-stuff, etc.), via collaborating with universities, scientific research institutions, partners and other parties, after exploration and practice, the SBR aerobic granular sludge reactor is developed and launched.

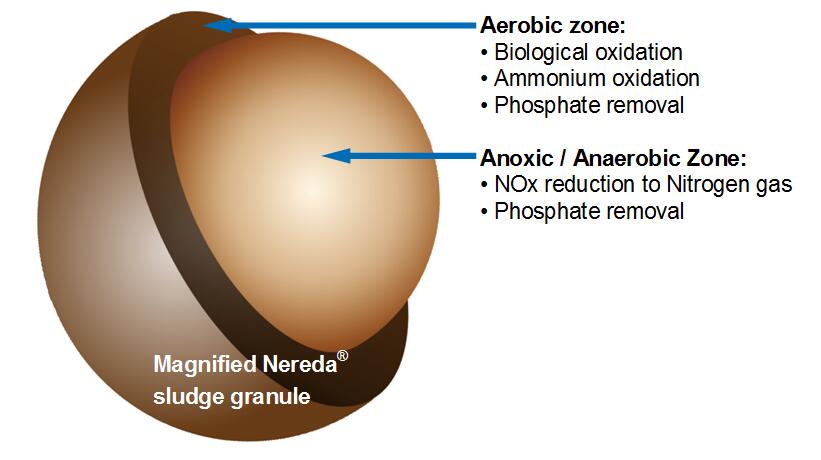

The SBR AGS reactor operates as the classic SBR and is based on the principle of hydraulic selection to continuously discharge the lighter sludge in the reactor out of the system to achieve the improvement of sludge settling performance. By this process, the realized SVI of sludge is less than 50 ml/g.

This process not only improves the settling performance of sludge, but also results in excellent biochemical properties of the sludge. It is better than conventional treatment processes in the removal of COD/BOD as well as nitrogen and phosphorus pollutants. More important, for the occasions where wastewater contains high level of refractory and bio-inhibitory pollutants, or high salinity (TDS), or in case the influent has a frequent and large fluctuation in both composition and hydraulic load, the process still remains good treatment performance.

This technology has the following characteristics:

• Suitable for demand of Chinese treatment market

After long-term development, the coverage of wastewater treatment facilities is currently rather high (especially in the municipal field), and the market has entered the “stock era”. With the continuous economic development and improved environmental quality management requirements, a large number of existing facilities are currently facing pressure of more stringent discharge or in-situ capacity expansion and transformation requirement.

The SBR AGS reactor responds well to above demand. It can be transformed from the existing facilities in a fast-track way to quickly achieve the objective of improving effluent quality or treatment capacity.

In addition, taking into account the limited quality of grassroots personnel in many treatment facilities and the overall poor operation, maintenance and management capabilities, the system operation control and management are optimized, and equipment and instruments with large maintenance requirements in the AGS process are streamlined. This allows existing operation and maintenance personnel to get started quickly and better master the operation and management of the new system. Moreover, with optimized auto-control system settings, the due automation performance and operational stability are ensured.

• Solving difficult problems of treatment in some industrial wastewater

For some heavily polluting enterprises (esp. process industries such as pharmaceuticals, chemicals, dye-stuffs, etc.) or industrial parks, the composition of wastewater is complex, containing high levels of components that are difficult to degrade or have significant adverse effects on the bio-treatment process. And this is often accompanied by issues like high salinity, properties variation of wastewater due to changes of production process, raw materials, etc., and the flow also fluctuates greatly. Due to the poor biodegradability of this type of wastewater and the very stringent discharge requirements (normally compliant discharge at all times), how to get reliable bio-treatment performance and meet the discharge requirements is a long-standing problem plaguing the wastewater treatment industry. Currently, it is often done through lengthy treatment process and residence times, and supplemented with tertiary treatment with higher operating costs.

The SBR AGS process copes well with these problems. Practical experience shows that when this technology is applied to the above scenarios, the system has good resistance and tolerance to components in wastewater that negatively impact microorganisms, and its operating performance is stable. Furthermore the reactor volume is significantly smaller than that of conventional bio-treatment processes.